iLAM PRO Auto

SCALABLE. SIMPLE. INNOVATIVE. VERY PRO FOR ANY KIND OF JOB. The iLam Pro offers best-in-class lamination technology and unparalleled consistency of the final product. The use of oil-heated rollers ensures the best heat distribution and temperature maintenance over the entire surface. Intelligent temperature programme and quality components prevent overheating.

iLAM PRO Handfed

Up to format 380mm x 700mm

Maximum size: 380mm x 700mm Minimum size: 210mm x 297mm Thickness between 130 and 350gr/m2 Feeder up to 200mm Speed: 10m per minute 1,300 SRA3 sheets per hour

User-friendly

The machine is controlled via a touch screen. The iLam Pro features an automatic start-up function, a fast charging system, a multi-safety monitoring program and automatic temperature control. All these features guarantee rapid start-up and operation.

Heavy duty

With its solid steel base and tower construction, the iLam Pro's roller calibration is guaranteed for life, its pressure of 35.5 Newton/mm linear attests to its amazing strength.

Modular

Want to upgrade your iLam Pro with a power supply unit? The new iLam Pro is designed to do just that. You can easily connect the feeder, so you can really switch both production and automation.

MiniLAM B3

SIMPLE. INNOVATIVE. VERSATILE.

MORE POWER BEHIND YOUR LAMINATION WORK.

Designed to be the fastest and easiest-to-use machine, with the added feature of digital foil printing technology. Up to 2,500 sheets per hour.

Up to format 380mm x 700mm

Maximum size: 380mm x 700mm Minimum size: 210mm x 297mm Thickness between 130 and 350gr/m2 Feeder up to 400mm Speed: 15m per minute 2,000 SRA3 sheets per hour

User-friendly

The machine is controlled by a touchscreen. The MINILAM B3 offers an Auto Start function, fast film loading system, multi-safety monitoring programme and automatic temperature control. All this ensures quick start-up and fast operation.

Heavy duty

With its solid steel base and tower construction, the Minilma B3's roller calibration is guaranteed for life, its pressure of 35.5 Newton/mm linear attests to its amazing strength.

Versatile

With a speed of up to 2,500 sheets per hour, Minilam B3 stands out for its dual film changer that allows two film reels at the same time and its liftable feed, perfect for short runs and sheet sizes outside specifications.

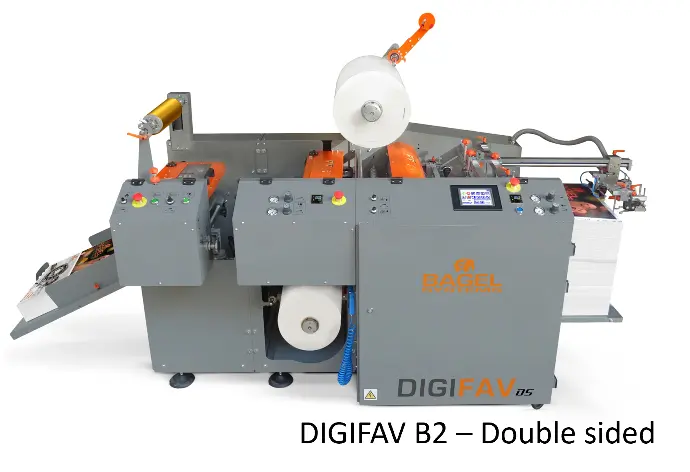

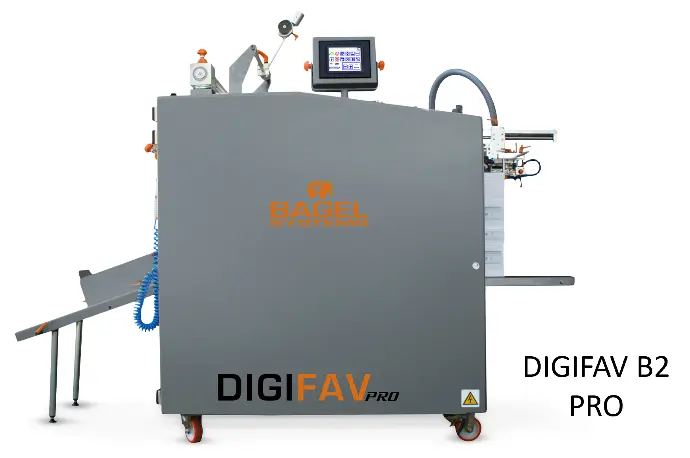

DigiFav B2

PERFORMANCE WHEN LAMINATING TO THE EDGE.

Robust and ultra-compact construction.

Consistent quality laminate up to 3,700 sheets per hourRequest for a Brochure

Up to format 530mm x 750mm

Maximum size: 380mm x 700mm Minimum size: 220mm x 220mm Thickness between 130 and 350gr/m2 Feeder up to 600mm Speed: 25m per minute 3,700 SRA3 sheets per hour

User-friendly

The height-adjustable, rotating touchscreen with automatic start function, fast film loading system, automatic temperature control and security monitoring of multiple systems all ensure fast start-up and production.

Heavy duty

With its solid steel base and tower construction, DIGIFAV B2's roll calibration is guaranteed for life. Its stacking capacity of 200 kg, roll pressure of 100.5 Newton/mm and ability to burst films up to 75 microns are proof of its durable construction.

Productivity

Enables speeds of up to 3,700 sheets per hour, infeed stack up to 600 mm high. DIGIFAV B2 can operate in 2- and 3-shifts per day. The ability to spread offset spray powder along with automatic film loading and start-up minimises production downtime and reduces job changes to less than a few minutes.

Sleeking with the DigiFav B2

FALCON B1

BUILD FOR EPIC PRODUCTIVITIES AND EVERYTHING ELSE.

A giant leap forward in lamination, radical in automation and yet perfectly logical up to 4,000 sheets per hour

Up to format 750mm x 1050mm

Maximum size: 750mm x 1050mm Minimum size: 300mm x 300mm Thickness between 130 and 450gr/m2 Feeder up to 840mm Speed: 35m per minute 4,000 SRA3 sheets per hour

Automation

It is radical in terms of automation, test completely logical, Falcon B1 is controlled by Plc, start-up is automated and film threading too; Precise sensors are set to control plate positioning. The temperature programme anticipates energy fluctuations, so the FALCON B1 automatically readjusts the power of the heating system.

Heavy duty

Tons of power inside. The solid steel base, tower construction, quality components, 500 kg feed stack capacity, 78 Newton / mm linear pressure and heavy-duty film crane make the Falcon B1's most durable and strongest equipment in the field.

Quality

Whatever the job, the FLACON B1 is ready for it. The heating systems are oil-heated and ensure a homogeneous temperature at every point of the calender, 100% OMRON electronic components, the highest integration average and the heating coil is corrected and polished several times, so we have also increased energy transfer at the highest level.

FOILER 3D Auto

METALLIC ON TOP OF DIGITAL VARNISH.

SENSORIAL PRESSURE, SUPERCHARGED FOILER.With the best technological proposal on the market, FOILER 3D offers an unparalleled finish for medium and large-scale productions. This is possible thanks to the heating and pressure system, both oil-heated, very stable, very robust and equipped with greater accuracy.

FOILER 3D Handfed

Up to format 380mm x 700mm

Maximum size: 380mm x 700mm Minimum size: 210mm x 297mm Thickness between 130 and 350gr/m2 Feeder up to 200mm Speed: 10m per minute 1,300 SRA3 sheets per hour

User-friendly

Touch control screen, quick and start button; automatic plate registration, multi-system safety monitoring, temperature prediction programme, pressure that adjusts itself automatically and anti-scratch roll bar. All this so you can get a grip on it without realising it.

Heavy duty

Features a 5 mm thick steel platform and tower construction. FOILER 3D guarantees lifetime calibration reliability. The installed electronics (OMRON) are industrial and each device is exceptionally strong. All designed for intensive use.

Digital customisation

FOILER 3D does much more than just metallic and holographic effects on 3D surfaces. It is possible to foil digital toner ink; use it as a coater or spot coater. And, of course, a laminator…

Up to format 380mm x 700mm

Maximum size: 380mm x 700mm Minimum size: 210mm x 297mm Thickness between 130 and 350gr/m2 Feeder up to 400mm Speed: 15m per minute in production mode and 22m per minute in mechanical mode. 2,000 SRA3 sheets per hour

Premium quality

The MINILAM R2R offers best-in-class

lamination technology and unrivalled

consistency of the final product. The use of

oil-heated rollers ensure the best distribution of

heat and temperature retention over the entire

surface.

Heavy duty

With its solid steel base and tower construction,

The roller calibration of MINILAM R2R is

guaranteed for life. Its pressure is 101 Newton/mm

linear attests to its amazing strength.

Multifunctional

With a speed of up to 15 metres per minute,

MINILAM R2R stands out for its capabilities

roll-to-roll and sheet-to-sheet lamination

as well as digital hot stamping capabilities

lamination of larger sheets beyond specifications

semi-automatic mode

Want to discover even more about our products?

Back to our homepage